Participate in a subsidized experiment that customizes AI-powered inspection for your manufacturing company, made possible by Brainport Industries and AI-MATTERS.

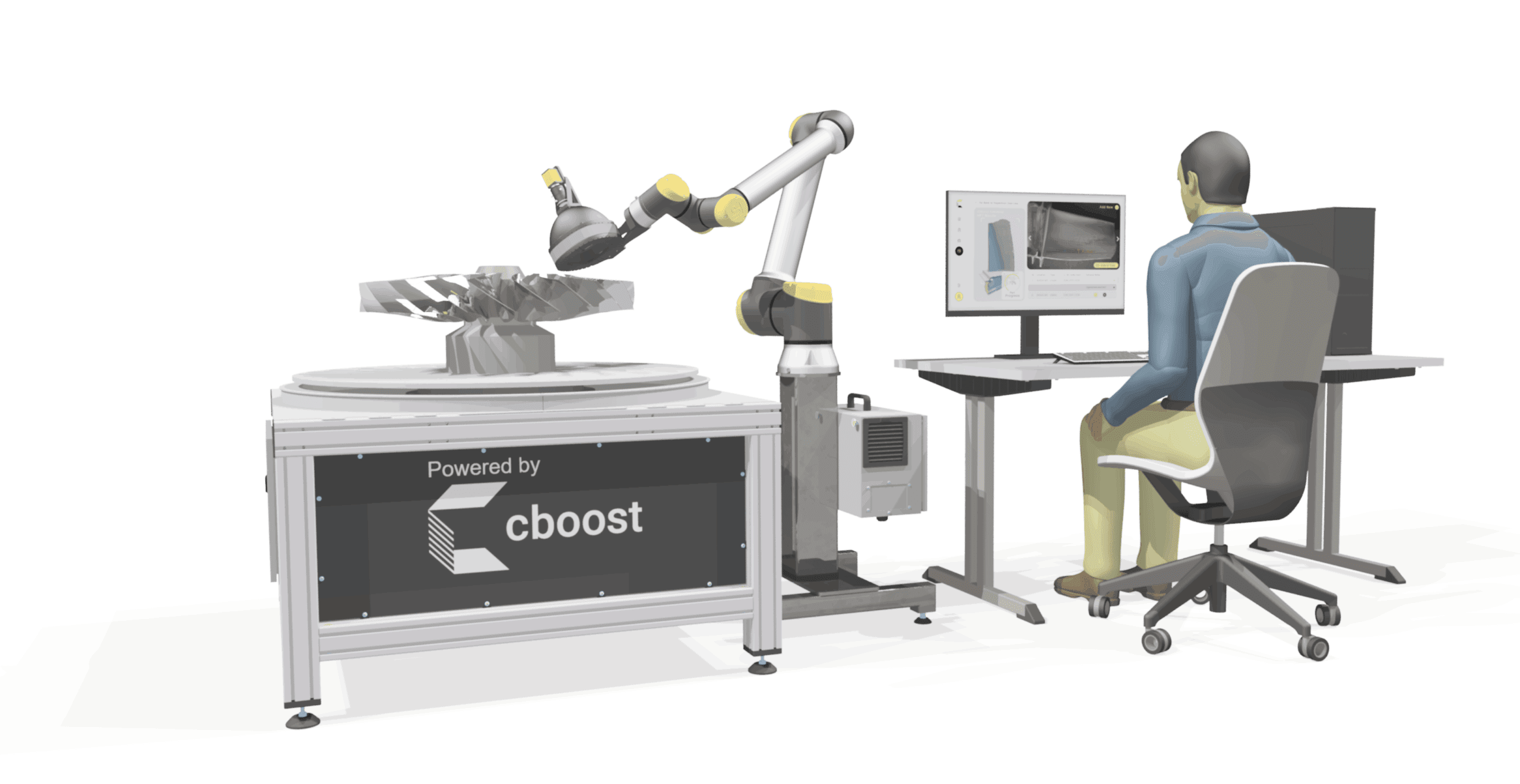

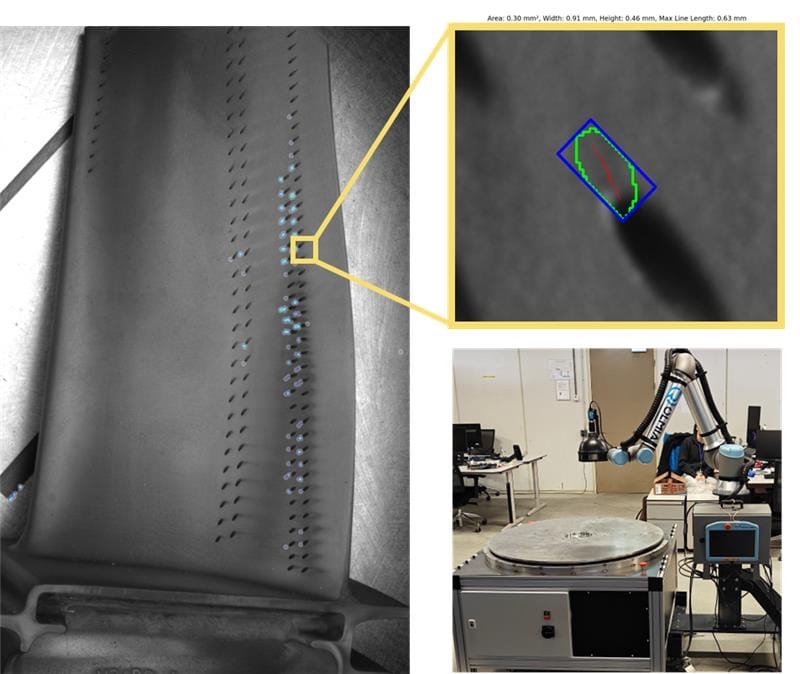

The experiment uses SensAI, our automated visual inspection system, to demonstrate what you can achieve with AI-based defect detection on high-quality surfaces such as metal or polymer. This system will serve as a proof-of-concept for the broader adoption of AI in quality assurance processes within the manufacturing sector.

We invite manufacturing SMEs seeking to upgrade their quality control standards, improve efficiency, and be the first to test next-generation AI visual inspection technologies.

Contact us now!

Do I need to invest anything?

No, there is no need for financial investment in the experiment stage. You will only need to provide a sample of parts.

What is the end result of this experiment?

You will get results, insights, and a roadmap to form the basis for an automated visual inspection system.

Who is financing this experiment?

The experiment is subsidized by Brainport Industries, as part of the AI-MATTERS project (TPS2D), supported by the European Union.

Brainport Industries is a consortium in the high-tech manufacturing sector, consistently driving innovation and enabling collaboration among key players in the Brainport Eindhoven region. Brainport Industries is advancing the AI-MATTERS project (TPS2D), which aims to accelerate the adoption and demonstration of AI solutions in industrial environments.

Cboost brings a proven track record in developing and deploying advanced inspection systems, combining high-resolution imaging with state-of-the-art AI algorithms. Cboost has been approached by Brainport Industries to design and deliver an experimental set-up that will showcase the practical application of AI-powered visual inspection under real-world manufacturing conditions.