Explore how AI inspection systems such as SensAI are transforming quality control in aviation and high-value manufacturing, reducing risk, and accelerating compliance.

In industries like aerospace and advanced manufacturing, quality is non-negotiable. The room for error is razor-thin, and missed defects can affect safety, compliance, reputation, and the bottom line. Demands placed on quality assurance have evolved significantly. Inspection systems have to be faster, smarter, and more robust than ever. They need to keep up with modern production lines and ever-stricter regulations.

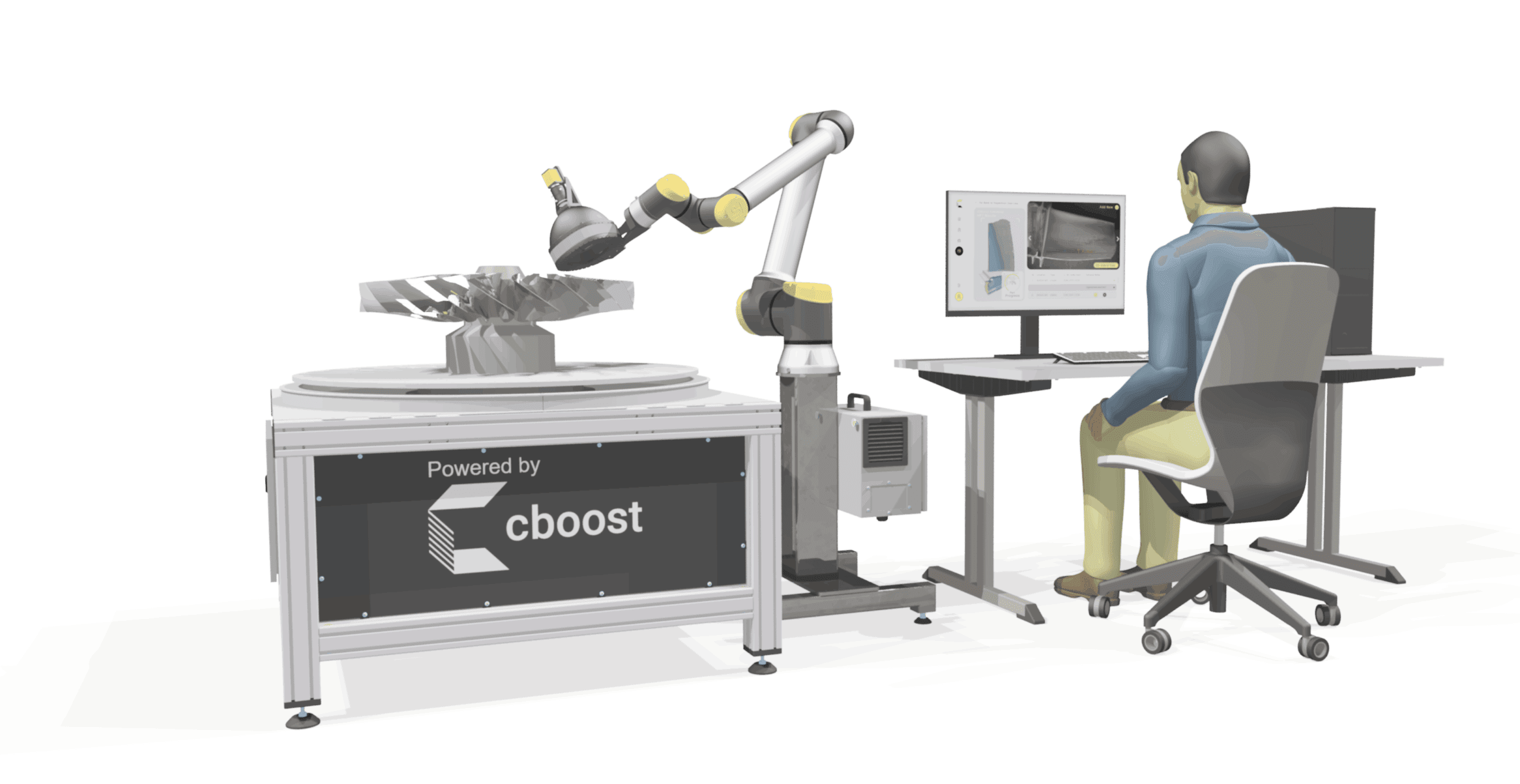

SensAI, an automated visual inspection system, can be the solution. It uses high resolution cameras, sensors, lighting, and advanced AI to quickly and accurately detect defects. It provides consistent, real-time quality checks without human error, and supports traceability and compliance.

The real cost of traditional inspection methods

21st century industries call for an upgrade from traditional inspection methods to automated visual inspection. This is especially relevant in industries where high quality and precision are not a nice-to-have, but they are critical.

Manual inspection processes are prone to errors, subjective, and slow. It is also more likely to have a negative impact on the economic and operational aspects of your company. Think of customer complaints, costly recalls, or even major safety issues. In aerospace, for example, a single missed defect can lead to tens of thousands in costs due to delays and downtime.

Manual inspection methods can’t keep up with the increasing complexity and regulatory scrutiny in industries where the stakes are high. Production lines, especially in aerospace and advanced manufacturing, are now faster, more customizable, and highly traceable. Quality control should keep up.

Achieve better inspection results with less costs and less time

Thinking of implementing an automated visual inspection system such as SensAI in your process? Here is how it works:

- The hardware set-up is optimized according to your use case

- Once set up, data will be processed in cloud or at edge, on-site or off-premise

- An AI model trained on your data identifies the defects of your choice

- Operator receives full report on system(s) of choice

Choose SensAI and you will…

- Reduce inspection time by 70%-80% thanks to the automation of admin-related tasks

- Increase defect detection rate by 18% on micron-level

- Mitigate potential client disputes regarding compliance or defects through automated reporting

- Reduce downtime with faster ROI, and adaptability to new product introductions

- Enhance safety and regulatory alignment

Working with the right supplier can be a game changer

While it sounds promising, an automated visual inspection system will not add value to your inspection process if you don’t partner with the right supplier. A lot of inspection companies promise more than they can deliver. This is why it is important to have a clear overview of what the project will look like from day one.

Why Cboost is different

1. Decades of experience and solid track record

Our multidisciplinary team has a total of 50 years of experience in hardware, software, and AI. Together, they have built an extensive track record in AI solutions for aviation, logistics, manufacturing, and more.

2. Advanced AI models and constantly innovated and updated technology

Not only does Cboost develop state-of-the-art products that will always be in line with the latest technology, but we also innovate in-house.

3. Operational impact

Cboost helps you set clear goals that sustain the growth of your business. Whether you want to improve standardization and scalability of quality checks or increase production capacity and reduce dependency on manual processes, Cboost can show you what is possible in terms of visual asset inspection.

4. Cultural shift

Cboost knows that with every new product, the team’s buy-in is essential. After all, it’s not just about technology, but about the people who will use it. With a collaborative approach combined with clear planning and visualization, Cboost can help you raise awareness among employees about the importance of automation.

5. Transparency and clarity

Throughout the entire project, transparency and clarity are of utmost importance for Cboost. The dedicated multi-disciplinary team provides a clear plan with well thought out decisions, with plenty of room for feedback and collaboration.

Whether your operation requires in-line, stationary, or image-based quality checks, automated visual inspection stands out as the modern answer to today’s quality challenges. The right AVI system detects defects while providing real-time data for decision-making, enhancing compliance, and empowering companies to improve continuously.

Read more about the value Cboost creates here.

When quality can’t be compromised, working with the right partner makes all the difference. Effective automation depends on partnering with a provider who combines proven experience, technological innovation, and a deep understanding of your industry’s unique needs. This is where Cboost sets itself apart. With SensAI, we offer an advanced product, a transparent project approach, and the collaborative mindset necessary to support both technological and cultural transformation.