Damage detection on airplane engines at a micron level for KLM Air France

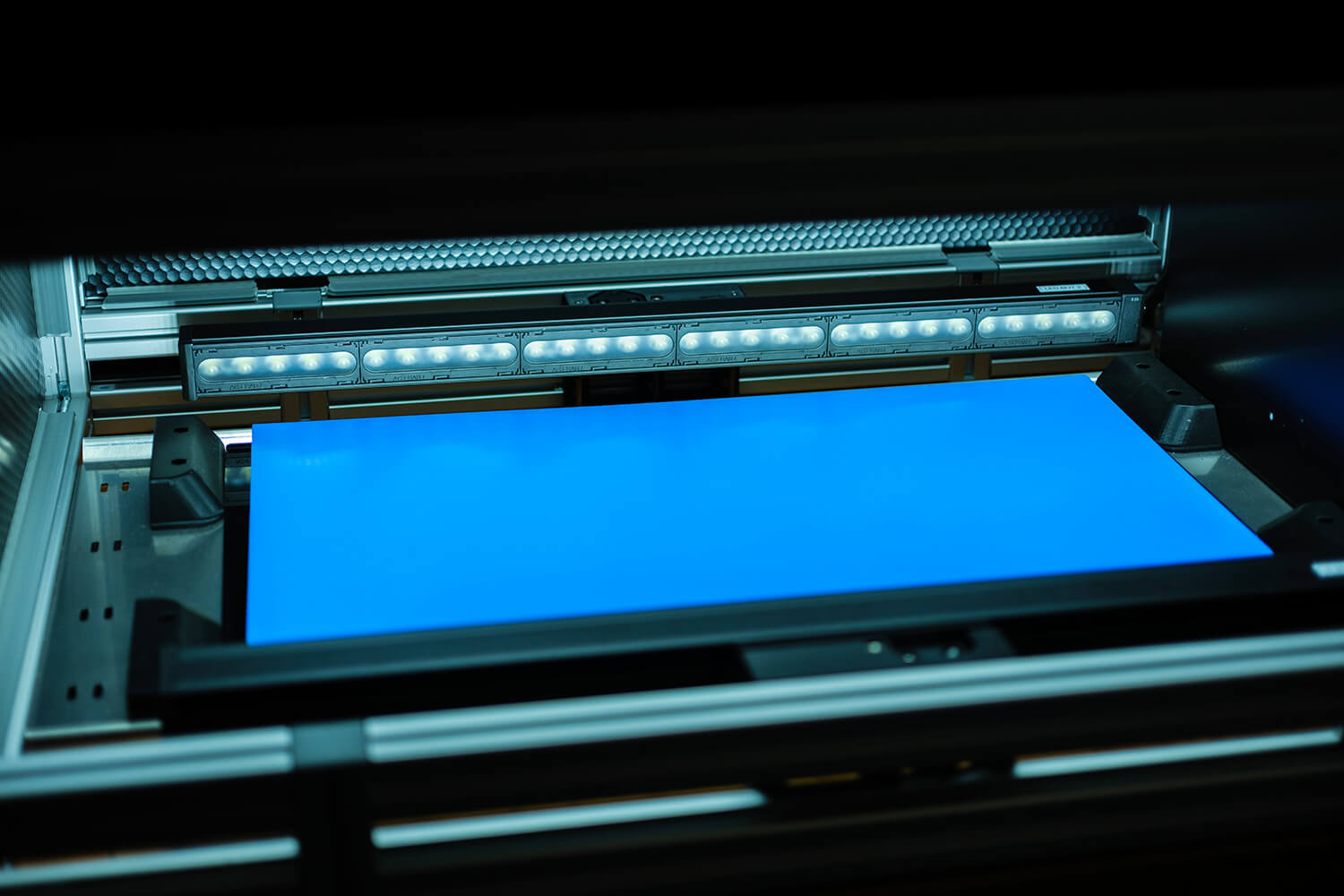

To preserve essential expertise in airplane engine inspection, Cboost is working on an automated visual solution using AI-powered Computer Vision together with Air France KLM Engineering and Maintenance.

- A custom data collection setup was used to gather high-quality data

- Damages were detected on a micron level using a pre-trained AI model enriched with the data collected

The LVS is improving the battery measurement process of Landport Batteries

Using IoT technology and emedded systems engineering, Cboost developed the Landport Voltage Sensor (LVS) that measures battery voltage in real-time. Currently, over 2000 LVS are on-site providing real-time information on voltage to enable optimized charging planning.

- Enabled real-time insights into battery status, substantially reducing costs

- Optimized charging schedules

- Reduced reliance on manual labor

Water-Tech prevents water damage and technical failure with sensors and AI software

Water damage often occurs invisibly and can quickly disrupt technical installations. To solve this challenge, Cboost started Water-Tech in collaboration with VDB Vochtwering. As part of Water-Tech, Cboost developed an AI-driven software that uses data from smart sensors on-site to predict the risk of water damages and leakages through constant and real-time monitoring.

- Water-Tech offers a platform linked to advanced sensors for monitoring water detection, water level, humidity, temperature and conductivity.

- The platform automatically warns of detected flooding based on preset maximum values so that measures can be taken in time against further flooding.

Scaling and standardizing quality inspection of polyurethane products for PolyMX

To reduce reliance on manual labor and maintain consistency at scale, Cboost is developing an AI-powered visual inspection solution for PolyMX. This paved the way for a standardized, scalable, and highly accurate inspection process.

- Successfully completed a technical audit to determine the project’s feasibility.

- Achieved over 80% accuracy in the testing phase.

- Reduced costs and reliance on human labor.