Powered by Cboost and Boerschappen. Choosing the Flexible Food Picker means choosing:

What is the Flexible Food Picker?

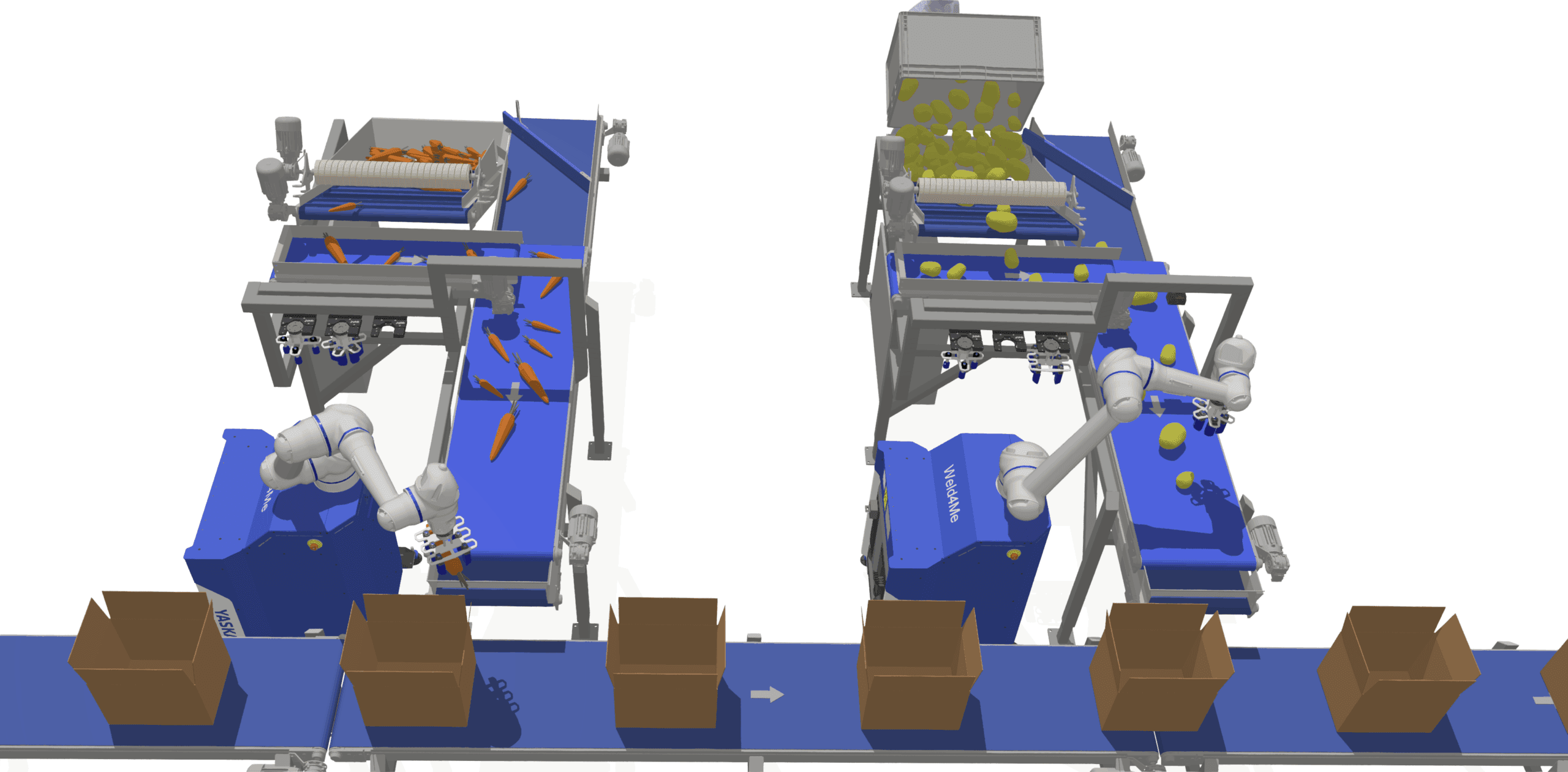

The Flexible Food Picker combines AI Vision and Robotics into an integrated system that turns picking and packing into an optimized, flexible process.

The Flexible Food Picker is a result of the collaboration between Cboost, Boerschappen, and partners, as part of the Interreg Smart Farming & Food Processing program.

Technical specifications

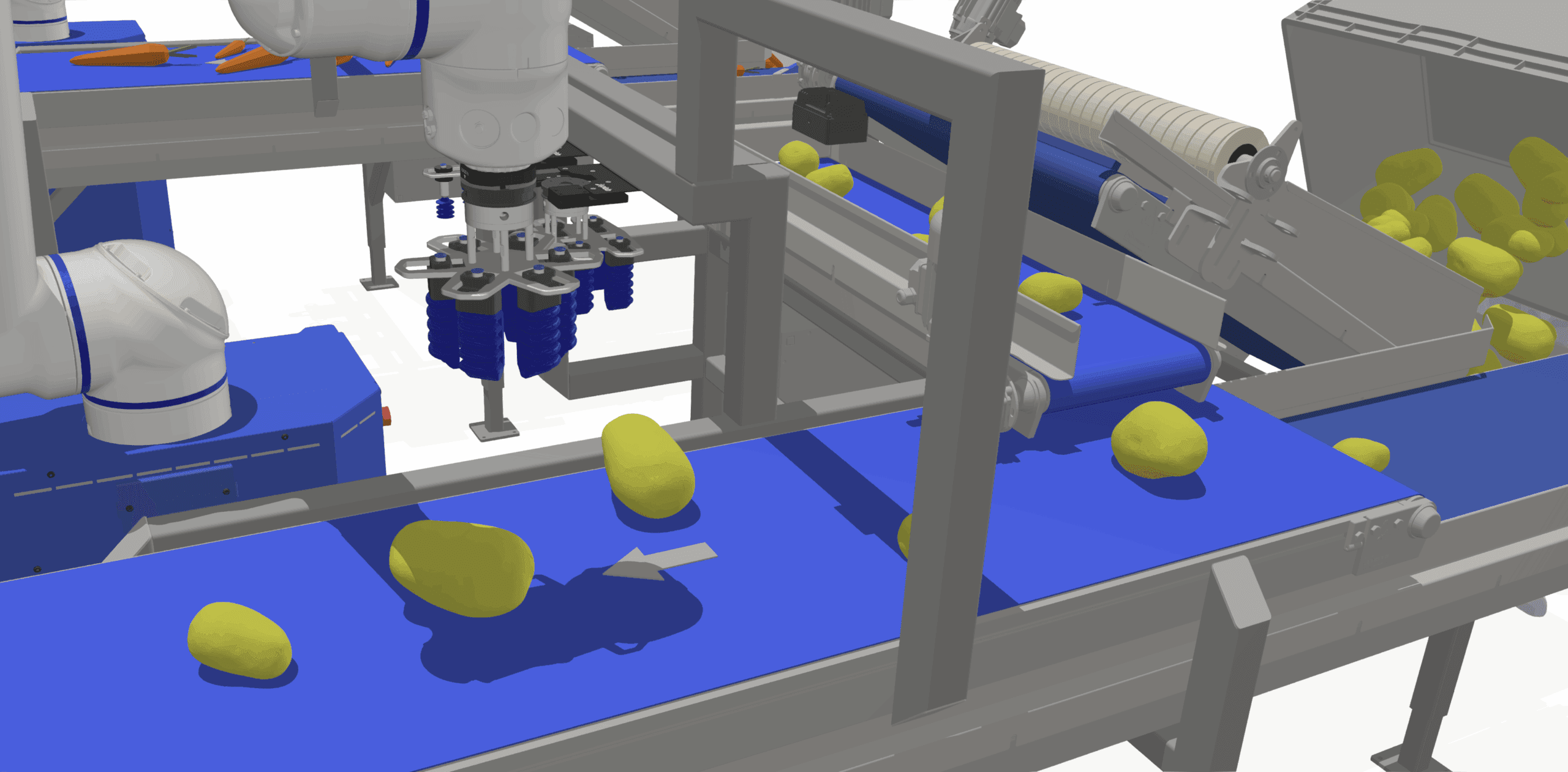

Robot Model: Yaskawa HC10DTP Cobot

Control System: Yaskawa YRC1000micro, Smart Pendant, Operational Stand

Number of Axes: 6

Payload: 10kg

Max Working Range: 1,379mm

Repeatability: 0.05mm

Robot Weight: 58kg

Power Supply: 1kVA

Max Axis Speeds: S/L (130°/s), U/R (180°/s), B/T (250°/s)

Pick Speed: Up to 5s per pick

Vision System: 2D Camera, 3D Camera

Gripper: Flexible, with tool changer and docking station

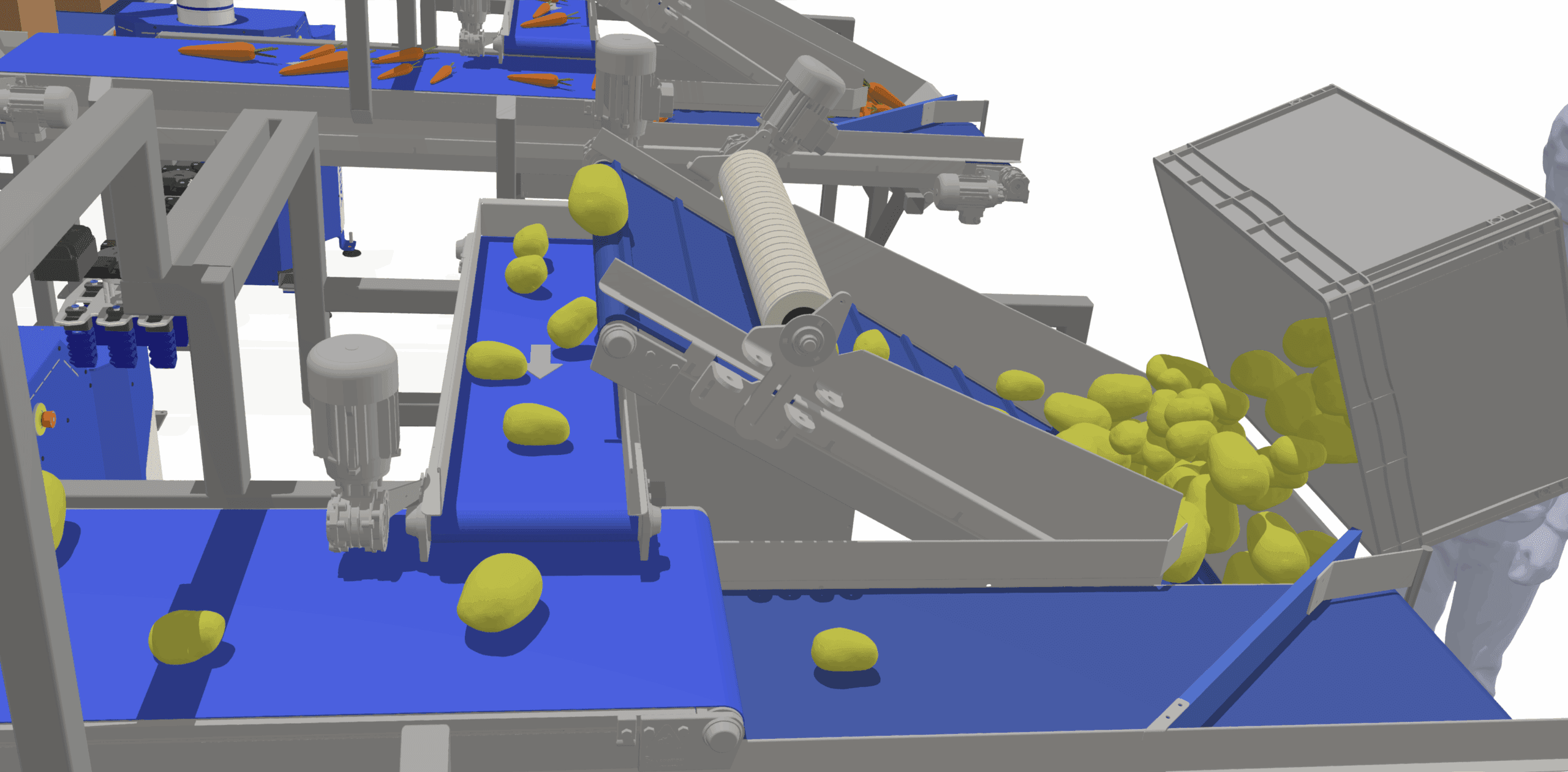

Conveyors: Supply belt, Transport belt

Additional Hardware: Hopper modification, PC, Printer, Clipper, Draaitafel, Banderol with printer

Operating Software: ROS 2 (Robot Operating System)

Note: The set-up can be customized according to client needs

Ideal for:

- Small to large sized farms

- Farms with organic and biological values

How it works

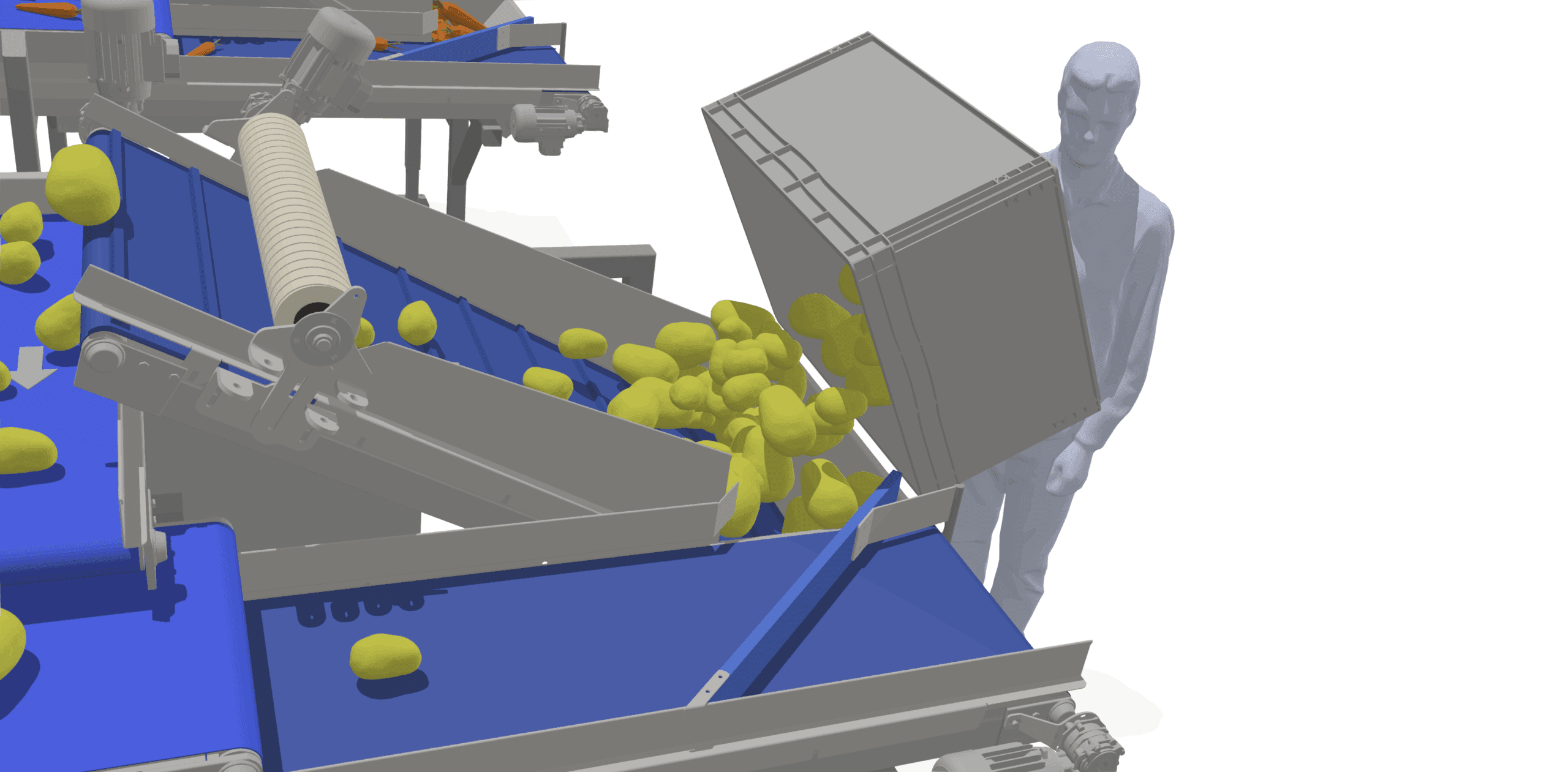

The operator places fresh food onto the diagonal conveyor belt.

The fresh food is scanned by a vision camera which communicates with the robotic arm.

The robotic arm picks up the fruit or vegetable with its adaptive gripper.

The robotic arm places the fruit or vegetable into the correct box.

Why work with us

- Track record in handling high complexity, low volume manufacturing

- Multidisciplinary team with decades of experience in hardware, software, and AI

- Seamless integration with processes and systems

- For increased efficiency and sustainability