Achieve faster and more accurate inspection at a micron level with SensAI, our innovative automated visual inspection system.

What is SensAI?

SensAI uses our proprietary AI, advanced imaging technology, and robotics to automatically inspect defects or quality issues during manufacturing, providing real-time, actionable reports to operators.

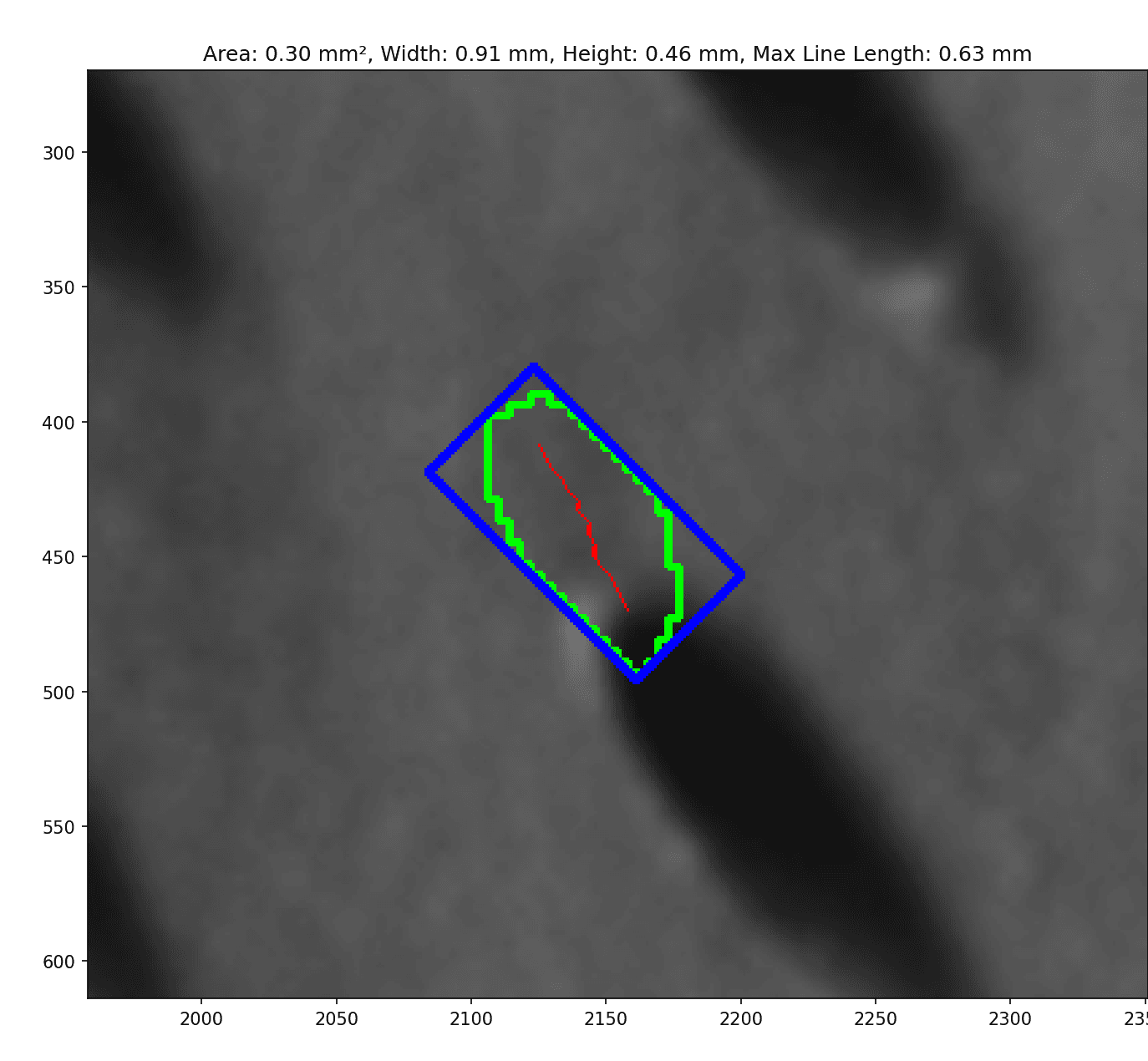

Thanks to high-resolution cameras and AI, the system can detect flaws at a micron level on high-quality surfaces of complex parts. By combining this with our robotics hardware, SensAI can handle a wide variety of parts. The results and output can be seamlessly integrated into manufacturing processes for optimal quality control.

Ideal for companies with high-quality, complex production needs in:

- Manufacturing

- Aerospace & aviation

- Semicon

How it works

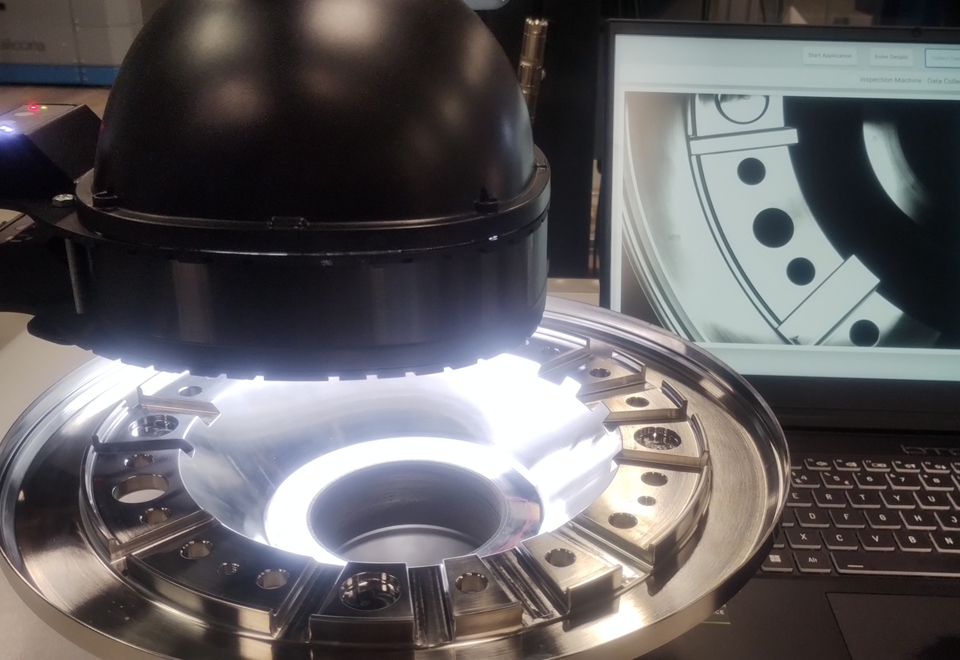

Hardware set-up

The hardware set-up is optimized according to your case, using a combination of robotics, lighting techniques, and intelligent cameras.

Data processing

Once set up, data will be processed in cloud or at edge, on-site or off-premise

Defect detection

Cboost’s proprietary AI models identify defects

Inspection report

Operator receives full report on system(s) of choice

Why work with us

- Track record in AI solutions for aviation, logistics, manufacturing and more

- Multidisciplinary team with decades of experience in hardware, software, and AI

- Seamless integration with your processes and systems

- For increased efficiency and sustainability