AI visual inspection for airplane engines

How Cboost helped KLM detect damages on airplane engines at a micron level

To preserve essential expertise and reduce human error in airplane engine inspection, Cboost is working on an automated visual solution using AI-powered Computer Vision with the Air France KLM Engineering and Maintenance department.

Key outcomes

- More efficient and accurate inspection process with less reliance on manual labor

- In-house data collection process and hardware

- Damage detection at surface micron level

- Easy-to-use inspection reports seamlessly integrated into workflows

The challenge

The aviation industry is experiencing technical staff shortage and dependence on manual labor. Moreover, engines are becoming more complex (GEnx, CFM LEAP, composites) while aerospace regulations are becoming tighter.

The Solution

Cboost developed a data collection setup from scratch using smart lighting, machine vision cameras, a rotational board and a robotic arm.

A pre-trained AI model was customized using the data collected to detect and classify damages at a micron level according to size, complexity, and severity.

The insights will be used to automatically create reports with an easy-to-use interface for visual inspection experts.

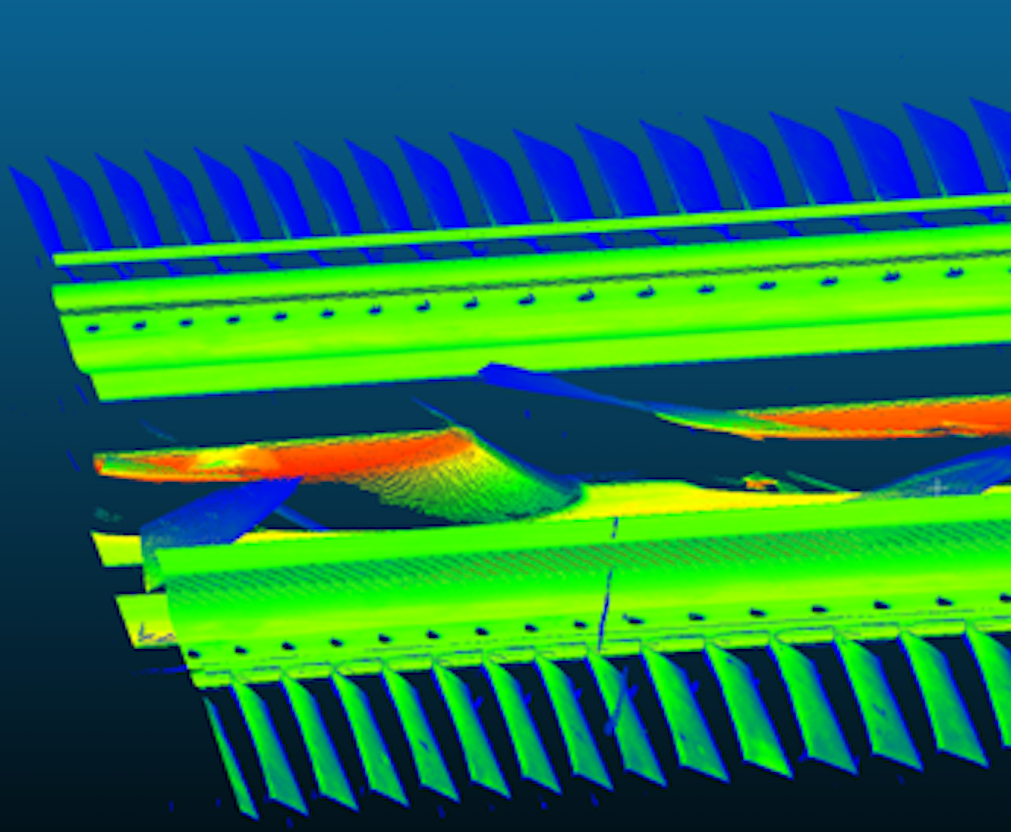

Point-Cloud Sensing

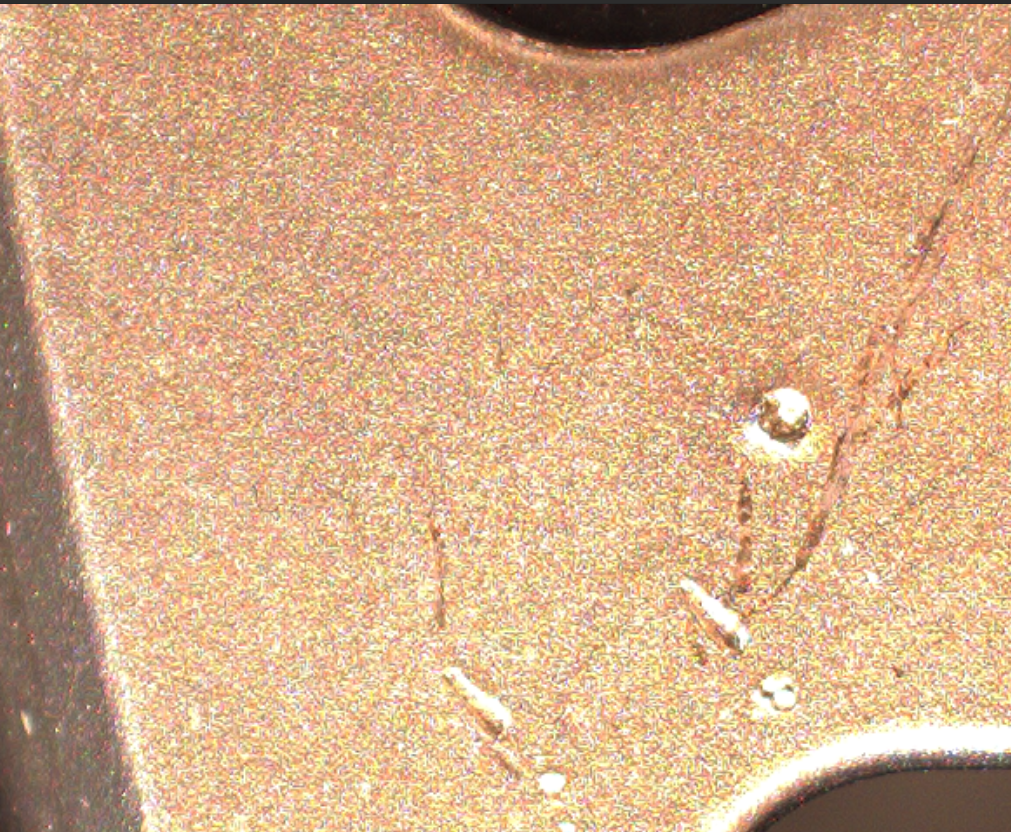

Smart lighting