AI Vision for picking robots

Discover how Cboost increased the accuracy and item range of Smart Robotics’ Pick & Place robot.

Through an AI-powered Computer Vision Model, Cboost helped Smart Robotics improve the efficiency of their Smart Item Picker. The award-winning solution developed and implemented by Cboost increased the Pick & Place robot’s accuracy and throughput for hard-to-pick items, while improving the robot’s overall item range .

Key outcomes

- The robot's accuracy increased from 75% to 99.86%

- Throughput for hard-to-pick items increased by 50%

- The item range of the robot was improved

- The robot can be safely managed by people of all skill levels

- The solution won first place in the Vanderlande picking challenge

The challenge

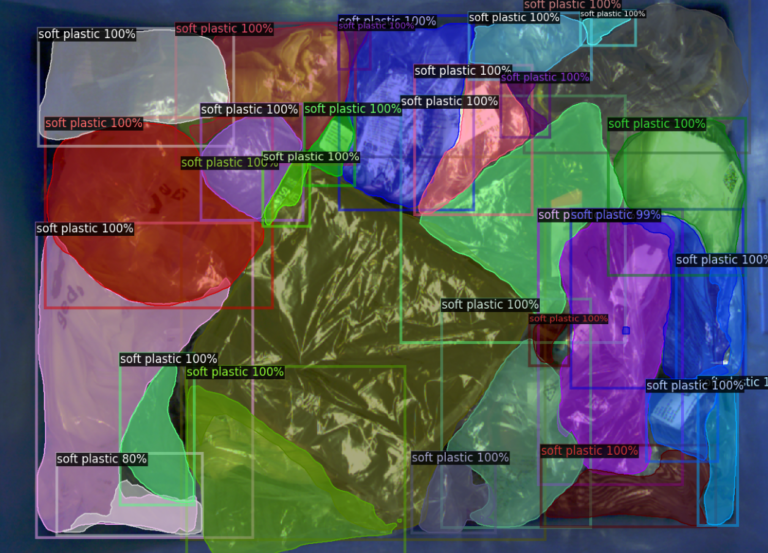

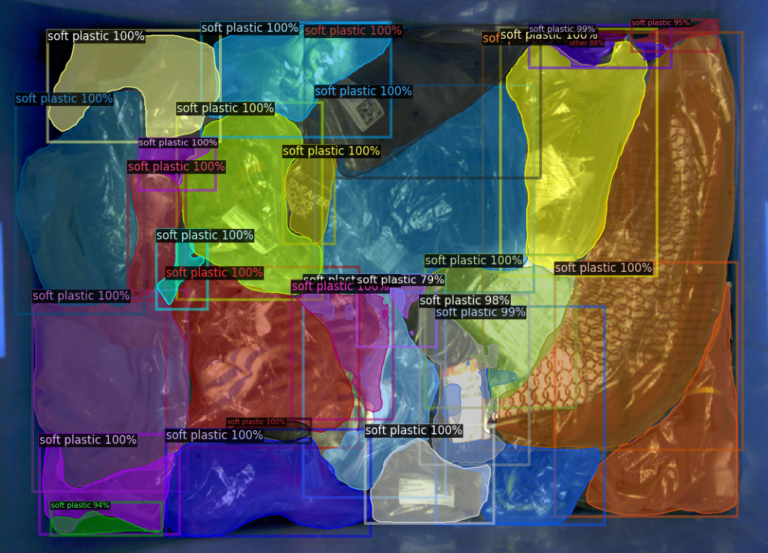

Smart Robotics provides unique technology and services to automate pick and place stations. Their Smart Item Picker experienced challenges with the reflection and refraction of fashion items placed in cardboard boxes or wrapped in transparent plastic. Moreover, their dataset was limited.

The Solution

Cboost’s AI and Machine Vision experts worked in tight collaboration with Smart Robotics for over two years to develop a custom AI model that would tackle the challenges experienced by their Smart Item Picker .

To overcome the limited amount of data, Cboost initially trained an AI using an already proven model and a transfer learning process. This led to setting up AI pipelines that seamlessly integrated within the Smart Item Picker. As a result, there has been a significant improvement in picking accuracy, item range, and hard-to-pick item throughput of the robot.

"With the help of Cboost's team, we were able to improve our item picking robot's item picking accuracy from 75% to 99.83%."

- Heico Sandee | CEO of Smart Robotics